High precision txhaj molds muaj tshuab txhaj tshuaj pwm

| Khoom siv | PC |

| Pwm Cavity | 2 Kab |

| Pwm Cavity Steel | 2344 (HRC48-52) XYOO |

| Pwm Txhaj System | Kub khiav |

| Pwm Ejection System | Ejector tus pin |

| Pwm Lub Sijhawm | 30 tus |

| Pwm Lub neej voj voog | 500,000 txhaj tshuaj |

| Lub Sijhawm Lead | 4 lis |

| Pwm puag | Customized |

| Khoom | Auto Parts Pwm |

| Daim ntawv pov thawj | ISO9001: 2015 |

| Pwm export rau | Teb chaws Europe |

| Pwm txiag | Shenzhen RCT MFG |

Dab tsi yog qhov siab precision txhaj pwm?

High precision txhaj tshuaj molding yog txheej txheem ntawm kev tsim khoom nrog nruj heev kam rau ua, feem ntau nyob rau hauv thaj tsam ntawm txhiab ntawm ib nti.Cov txheej txheem cuam tshuam nrog kev txhaj tshuaj molten yas rau hauv lub pwm kab noj hniav nrog kev ua haujlwm nruj heev, siv cov tshuab txhaj tshuaj molding siab.Cov pwm siv nyob rau hauv cov txheej txheem no yuav tsum muaj qib siab ntawm qhov tseeb thiab raug raws li lawv yuav tsum muaj peev xwm tsim cov khoom uas ua tau raws li qhov yuav tsum tau ua nruj me ntsis thiab xyuas kom muaj qhov sib xws ntawm ntau qhov kev khiav haujlwm.High precision txhaj pwm yog feem ntau siv hauv kev lag luam xws li cov cuab yeej kho mob, hluav taws xob, thiab aerospace qhov twg qhov kev ua siab ntev thiab qhov tseeb qhov ntev yog qhov tseem ceeb.

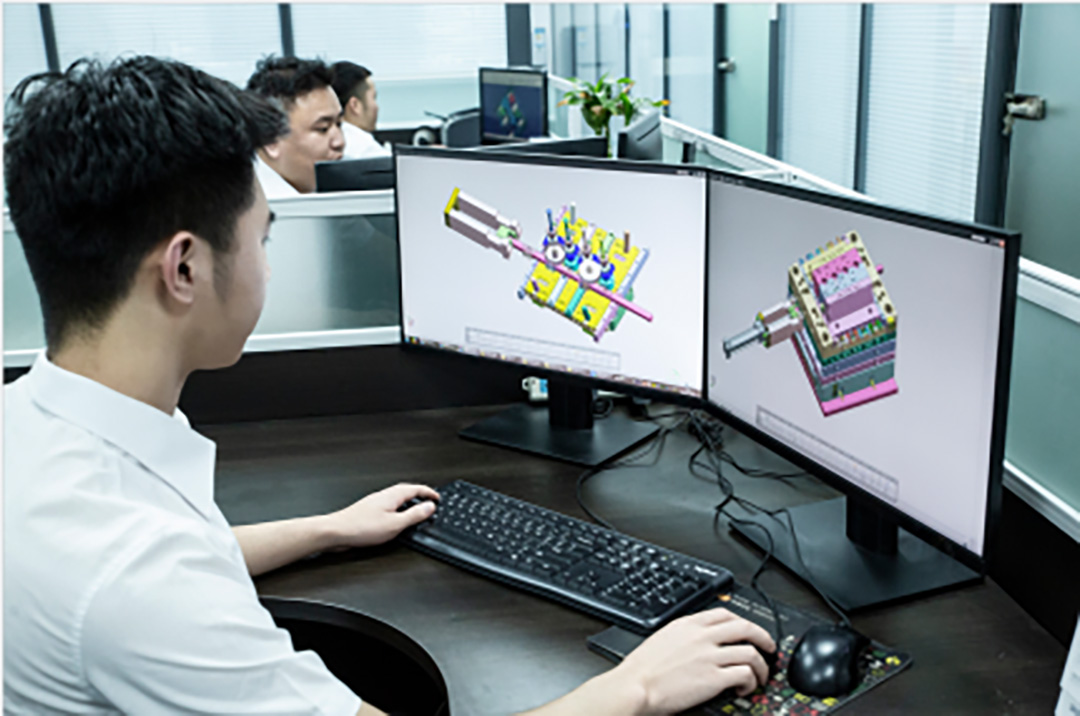

RCT MFG yog tus kws tshaj lij hauv kev tsim thiab tsim cov yas txhaj tshuaj pwm zoo thiab txhaj tshuaj molded qhov chaw tshwj xeeb rau kev lag luam thoob ntiaj teb.Peb muab OEM / ODM ntau lawm uas nruj me ntsis raws li tus qauv zoo pwm los ntawm peb cov neeg siv khoom thov.Peb txoj kev mob siab rau kev pabcuam peb cov neeg siv khoom nrog cov khoom zoo ntawm cov nqi sib tw thiab kev xa khoom raws sijhawm tau txhawb nqa los ntawm peb cov peev txheej txuas ntxiv hauv cov khoom siv, cov neeg ua haujlwm, thiab kev tswj hwm.

Peb lub peev xwm ua pwm thiab kev paub dhau los suav nrog:

●Tsev neeg pwm

●Ntau kab pwm

●Interchangeable inserts pwm

●Pwm nrog Ntau Sliders / lifters mechanism

●Pwm nrog floating core

●Kub khiav System pwm

●Unscrewing mechanism Moulds

●Tuag-casting

High precision txhaj pwm

| Cov khoom | Kev piav qhia |

| Pwm Core | DIN2312,2738,2344,718,S136,8407,NAK80,SKD61,H13 thiab lwm yam. |

| Hardness ntawm steel | 46-56 HRC |

| Molud Standard | HASCO, DME, MEUSBURGER, JIS, Tuam Tshoj LKM Standard |

| Pwm Base | LKM & Hasco & DME tus qauv (A, B phaj 1730,2311,2312, P20) |

| Cavity | Ib leeg/ntau |

| Tus khiav | Kub/Cold Runner |

| Qhov loj tshaj pwm | 1500 * 1500 hli |

| Nto Pwm | EDM / High Polish & Texture |

| Cov khoom siv yas | PC, PC + ABS, ABS, PBT, LCP, PBT + GF, POM, Nylon, PEEK, PE, HDPE, PP, AS, PS, PP + PULVISTALCI, PET, TPU, PPS, PSU, PPO |

| Pwm Lub Neej | 0.3 lab txhaj tshuaj- 1Million txhaj tshuaj (Cov khoom sib txawv steel sib txawv, min pwm lub neej 200,000 txhaj tshuaj) |

| Specification | Nyob ntawm cov neeg siv khoom xav tau. |

| Kev kho saum npoo | Polish, texture, painting, screen printing, turnkey project |

| Cov ntsiab lus lag luam | FOB Shenzhen, EXW, CIF |

| Export rau | Tebchaws Europe, Tebchaws Asmeskas, Mexico, Australia, Middle-East, Asia thiab lwm yam |

| Kub khiav system | Mould-MASTERS, INCOE, HUSKY, SYNVENTIVE, YUDO, EVIKON thiab lwm yam. |

| Pwm txias khiav | point rooj vag, sab rooj vag, subgate, qhov rooj vag, rooj vag txiv tsawb, ncaj rooj vag, thiab lwm yam. |

| Pwm kub kho | quencher, nitridation, tempering, thiab lwm yam. |

| Nto tiav ntawm Part | Logo luam ntawv, Texture, Polishing, Painting, Chrome Plating |

| Lub sij hawm xa tuaj | 4 mus rau 7 lub lis piam |

| Cov cuab yeej ntsuas | 3D Measurement, Profile Projector, Hardness Tester thiab lwm yam khoom siv tshuaj xyuas me me. |

| Sab nraud pob | Txheem ntoo rooj plaub lossis raws li koj qhov yuav tsum tau ua |

| Pem hauv ntej pob | Stretch waterproof zaj duab xis & Txhua Pwm pleev xim rau, anti-xeb roj.Cov khoom seem ua ke nrog pwm xa khoom. |

| Pwm cua txias system | dej txias lossis Beryllium bronze txias, thiab lwm yam. |

Txhaj Mould tu thiab tom qab kev pabcuam

"Txhua yam ntawm cov yas txhaj tshuaj pwm tsim thiab nyob ntawm RCT Mould rau kev txhaj tshuaj molding yog zoo tsim los tso rau tom qab molding ntau lawm, Core thiab kab noj hniav yuav tsum tau them los ntawm anti-xeb tshuaj, pwm phaj yuav huv si yam tsis muaj kev ntxhov siab, nws yuav raug sau npe thiab txheeb xyuas kom yooj yim rau kev nkag mus rau lub sijhawm tom ntej ntau lawm, peb xyuas kom meej tias nws muaj tam sim ntawd thaum twg koj xav tau cov khoom yas ntxiv, Txhua qhov kev hloov pauv ntawm cov yam ntxwv thiab pwm yuav raug kaw thiab taug qab tau. "

Txhua qhov kev txhaj tshuaj pwm rau kev xa tawm raug xa nrog 2D / 3D tsim duab kos duab, NC cov ntaub ntawv programming, kev txhaj tshuaj, ntsuas cov ntawv ceeb toom, thiab lwm yam, peb kuj muab EDM tooj liab, hloov pauv tau, thiab hnav cov khoom siv rau thaj chaw siv tau siv tau, qhov no yuav xyuas kom koj ua tu lossis hloov ntawm koj qhov chaw yooj yim heev.

Tiv tauj peb Hnub no los pib koj cov phiaj xwm txhaj tshuaj pwm

Peb muab cov khoom zoo ntawm tus nqi tsim nyog, qhov no yog vim li cas cov neeg siv khoom xaiv peb los ntawm peb cov neeg sib tw

Peb muaj cov engineers sib txawv suav nrog kev tsim, tsim, kev tswj kom zoo thiab kev muag khoom, txhua tus neeg txawj thiab cov kws tshaj lij nrog cov qauv pwm yas thiab txhaj tshuaj molding.

Hu rau peb pab neeg tam sim no thiab peb yuav tsis cia peb cov neeg siv khoom tawm mus yam tsis muaj 100% txaus siab, cia peb ua koj tus khub yas pwm uas txhim khu kev qha thiab muaj npe nrov.

Pwm machining tshuab