Cov khoom lag luam zoo tsis yog tsuas yog ua tiav, tab sis kuj xav tau ntau yam kev kho saum npoo kom ua tiav kev tiv thaiv corrosion, hnav tsis kam, zoo nkauj, thiab ua kom muaj kev pabcuam lub neej.RCT MFG muaj ntau xyoo ntawm kev paub hauv CNC ua thiab kev txhaj tshuaj molding ua, kuj muab ntau cov kev pabcuam los ntawm kev ua haujlwm rau saum npoo rau kev sib dhos.Yog li ntawd, ntxiv rau fabrication technology, nws kuj muaj kev nplua nuj nyob rau hauv kev kho deg.Cov txheej txheem kho saum npoo uas twb muaj lawm muaj xws li: pleev xim, ci xim, hmoov txheej, sandblasting, txhaj tshuaj blasting, anodizing, tuab zaj duab xis anodizing, micro-arc anodizing, electroplating, electrophoresis, laser engraving, silk screen printing, txhuam hlau, iav polishing, dyeing, blackening, CD qauv, etching, siab gloss, etch qauv, Epoxy, thiab lwm yam., pab ua kom koj cov khoom nyob rau hauv siab.

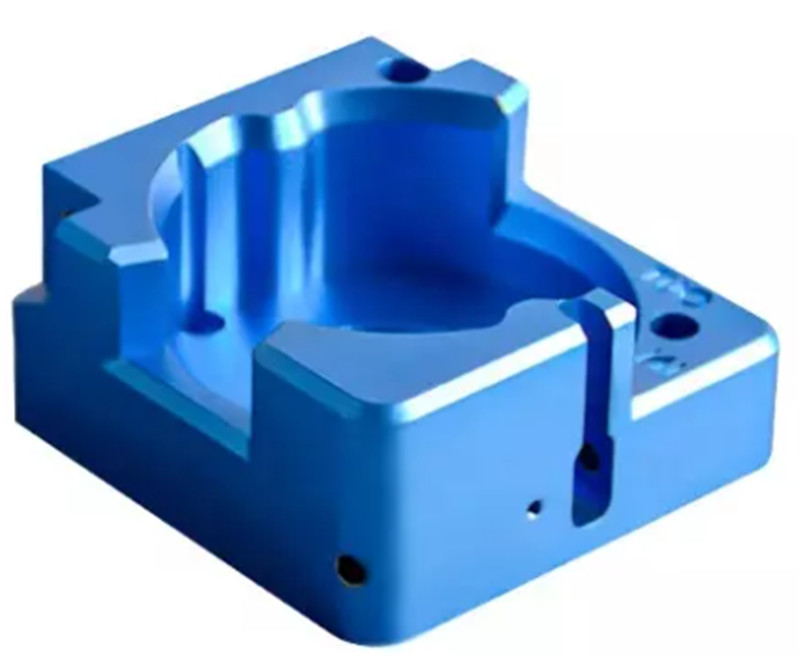

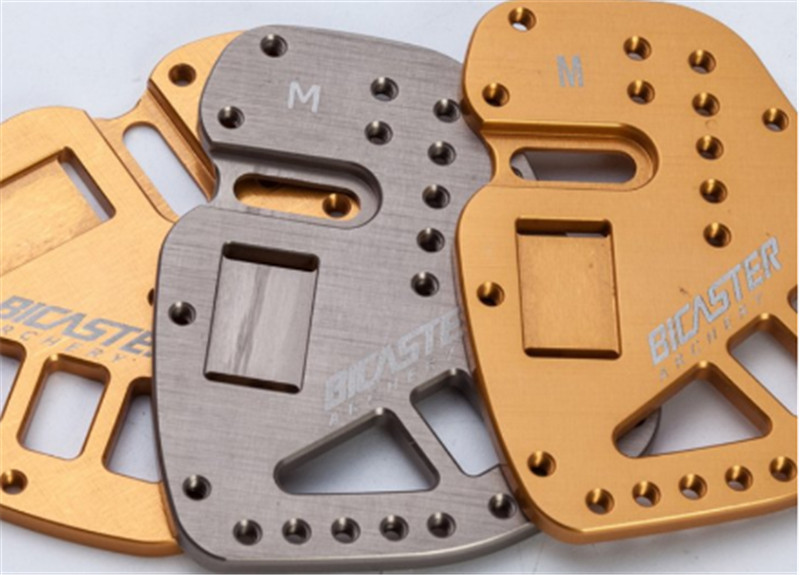

Anodizing

Nws yog cov txheej txheem electrolytic oxidation, uas hloov cov nplaim ntawm cov khoom mus rau hauv cov yeeb yaj kiab tiv thaiv, ua rau nws nyuaj rau oxidize thiab corrode, ua rau lub neej ntev thiab ua tiav cov tsos ntawm ntau yam xim.Feem ntau siv anodizing kev kho mob muab faib ua: ntau anodizing, txhuam hlau anodizing, nyuaj anodizing, tuab zaj duab xis anodizing, micro-arc oxidation, thiab lwm yam. Cov ntaub ntawv uas tuaj yeem oxidized yog: aluminium alloy, magnesium alloy, titanium alloy, thiab lwm yam.

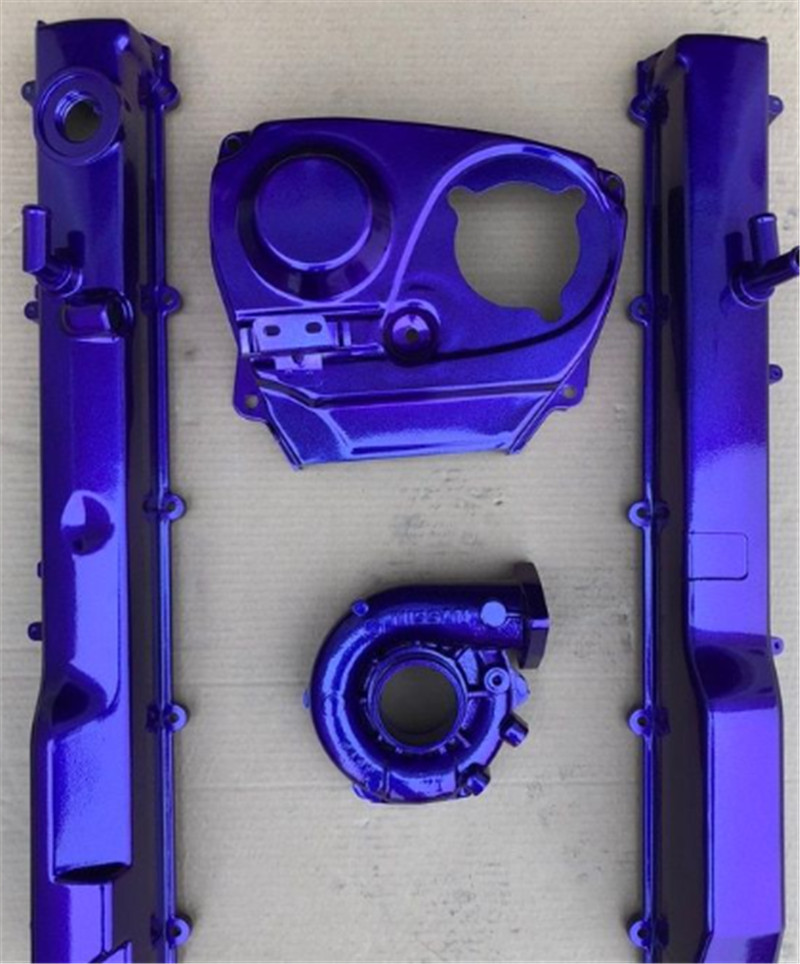

Electroplating

Cov txheej txheem tseem ceeb ntawm electroplating yog raus rau hauv qhov kev daws ntawm hlau ntsev raws li cathode, thiab cov phaj hlau ua cov anode, thiab dhau qhov tam sim no los tso cov txheej txheem ntawm qhov xav tau.Cov nyhuv electroplating tsim nyog yuav ua rau koj cov khoom lag luam muaj kev zam ntau dua thiab nrog nws.Rau kev lag luam zoo dua, cov txheej txheem electroplating suav nrog tooj liab plating, npib tsib xee plating, nyiaj plating, kub plating, chrome plating, galvanizing, tin plating, nqus plating, thiab lwm yam.

Electrophoretic txheej

Nrog rau kev txhim kho txuas ntxiv ntawm kev xav tau ntawm kev lag luam, Electrophoretic txheej tshuab tuaj yeem hloov kho ntau yam xim, tswj cov xim hlau thiab txhim kho corrosion tsis kam ntawm qhov chaw, uas muaj kev cuam tshuam me ntsis ntawm cov khoom raug.Lub thickness yog li ntawm 10-25um, thiab cov tuab tuab kuj tuaj yeem kho tau

Passivation

Passivation, tseem hu ua chromate kev kho mob, yog txheej txheem pickling uas tshem tawm cov roj saum npoo, xeb, thiab oxides los ntawm immersion los yog ultrasonic tu.Los ntawm cov tshuaj tiv thaiv ntawm cov tshuaj passivation, nws tuaj yeem tiv thaiv corrosion thiab ntev xeb.Cov xim ntawm cov zaj duab xis passivation yuav hloov nrog cov khoom sib txawv.Passivation yuav tsis nce lub thickness ntawm cov khoom, thiab tsis tas yuav txhawj txog nws cuam tshuam qhov tseeb ntawm cov khoom.

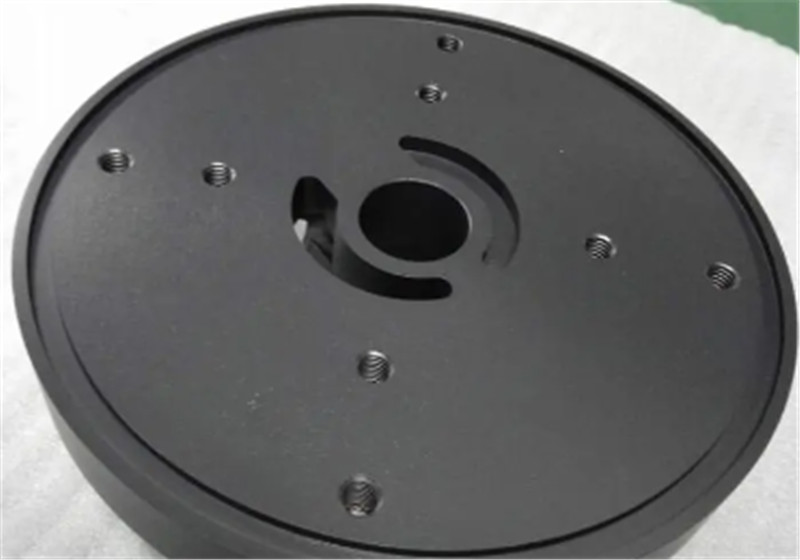

Dub

Blackening tseem hu ua bluing.Lub hauv paus ntsiab lus yog muab cov khoom tso rau hauv cov tshuaj oxidizing muaj zog los tsim cov oxide zaj duab xis ntawm cov hlau saum npoo kom cais cov huab cua thiab ua tiav lub hom phiaj ntawm kev tiv thaiv xeb.Cov txheej txheem no muaj feem xyuam rau cov ntaub ntawv steel.

QPQ (Quench-Polish-Quench)

Nws yog hais txog kev muab ferrous hlau qhov chaw rau hauv ob hom ntsev da dej nrog cov khoom sib txawv, thiab infiltrating ntau lub ntsiab rau hauv cov hlau nto los tsim cov txheej txheej infiltration, thiaj li ua tiav lub hom phiaj ntawm kev hloov kho qhov chaw ntawm qhov chaw.Nws muaj qhov zoo hnav tsis kam, qaug zog tiv thaiv, corrosion kuj thiab me me deformation.Cov txheej txheem no siv tau rau txhua yam khoom siv hlau.

(Ceeb Toom: Cov khoom siv hlau tsis tuaj yeem dub, thiab qhov chaw tsuas tuaj yeem dub los ntawm QPQ)

Laser engraving

Laser engraving, tseem hu ua laser npav, yog txheej txheem kho qhov muag siv cov qauv siv kho qhov muag los ua LOGO lossis cov qauv ntawm cov khoom.Cov nyhuv laser engraving yog ruaj khov, qhov zoo ntawm qhov chaw yog siab, thiab nws tsim nyog rau cov khoom ua los ntawm ntau yam hlau thiab cov ntaub ntawv yas.

Silkscreen luam ntawv

Silk screen printing txhais tau hais tias tus number case hloov cov qauv rau cov khoom los ntawm kev tshuaj ntsuam.Cov xim ntawm tus number case tuaj yeem kho raws li qhov xav tau ntawm cov neeg siv khoom.RCT MFG tau ua tiav 6 xim ntawm tib yam khoom, suav nrog dub, liab, xiav, daj thiab dawb., ntsuab.Yog tias koj xav tau cov nyhuv ntawm silk screen luam ntawv kom ntev dua, koj tuaj yeem ntxiv ib txheej ntawm UV tom qab silk screen luam ntawv kom ntev nws lub neej.Silk screen printing yog tsim rau ntau yam hlau thiab yas cov ntaub ntawv, thiab tseem tuaj yeem ua ke nrog kev kho deg xws li oxidation, painting, hmoov txau, electroplating, thiab electrophoresis.

Polishing

Polishing yog ua kom cov khoom zoo nkauj, translucent thiab tiv thaiv qhov chaw.Polishing thiab pob tshab yog qhov kev xaiv zoo rau koj.polishing ntawm cov khoom kho vajtse yog muab faib ua phau ntawv polishing, mechanical polishing, thiab electrolytic polishing.Electrolytic polishing tuaj yeem siv los hloov cov tshuab polishing hnyav, tshwj xeeb tshaj yog rau cov khoom uas muaj cov duab nyuaj thiab qhov chaw uas nyuaj rau kev ua haujlwm los ntawm kev siv phau ntawv polishing thiab kev siv tshuab.Electrolytic polishing feem ntau yog siv rau steel, aluminium, tooj liab thiab lwm yam.

Txhuam Txhuam Txhuam

Brushed hlau yog ib txoj kev kho saum npoo uas tsim cov kab ntawm qhov chaw ntawm lub workpiece los ntawm txoj siv tawv-nias abrasive thiab tsis-woven cov menyuam txhuam kom ua tiav cov nyhuv zoo nkauj.Kev kho mob txhuam hniav tuaj yeem cuam tshuam qhov kev ntxhib los mos ntawm cov ntaub ntawv hlau, thiab nws tau dhau los ua neeg nyiam nyob hauv lub neej niaj hnub no.Nws yog dav siv hauv xov tooj ntawm tes, khoos phis tawj, saib, rooj tog, khoom siv hluav taws xob thiab lwm yam plhaub.

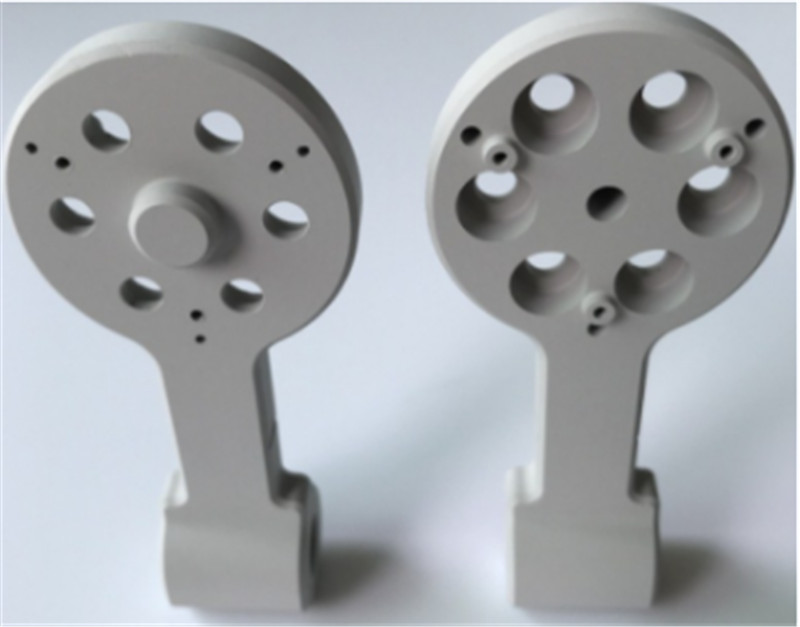

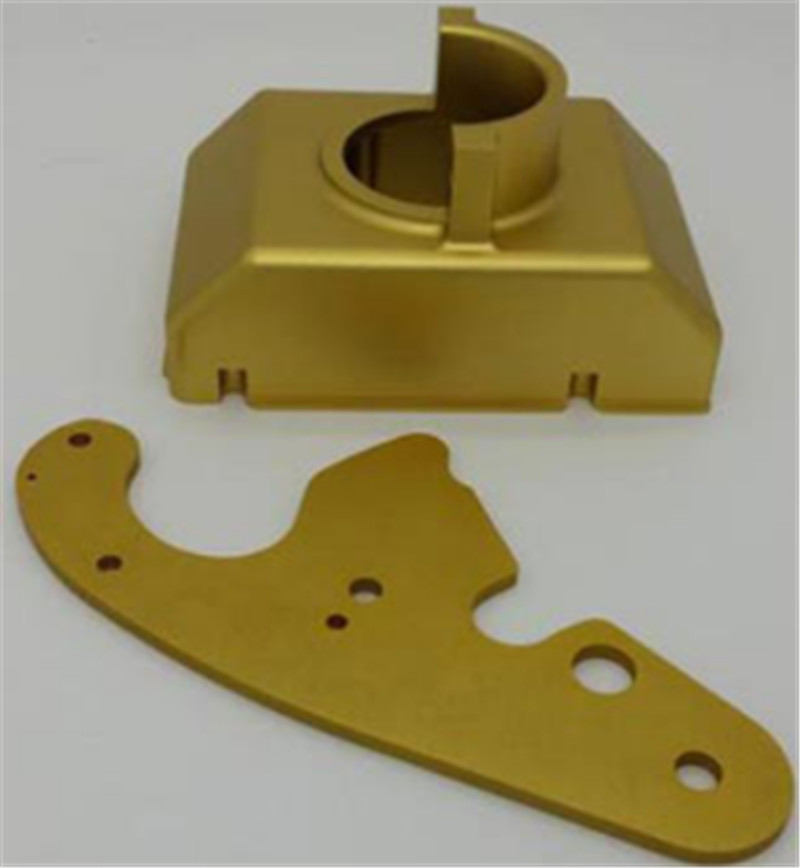

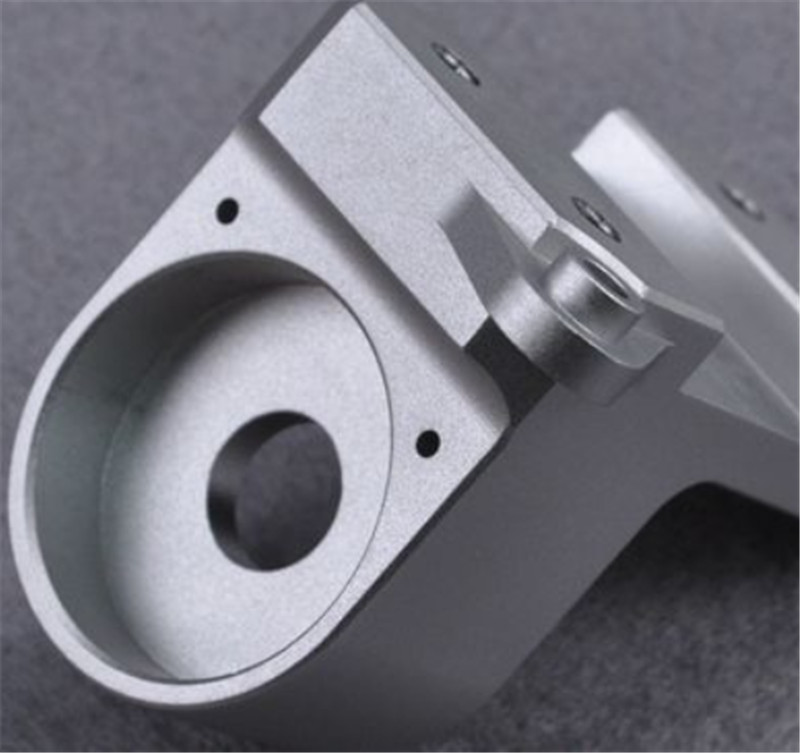

Xim txau thiab hmoov txau

Cov xim pleev xim thiab cov hmoov txau yog ob qho kev kho mob saum npoo hauv cov khoom siv tshuaj tsuag, thiab lawv yog cov kev kho mob feem ntau siv rau qhov tseeb thiab cov khoom me me.Lawv tuaj yeem tiv thaiv qhov chaw los ntawm corrosion, xeb, thiab tuaj yeem ua tiav cov txiaj ntsig zoo nkauj.Ob qho tshuaj txau thiab pleev xim tuaj yeem kho nrog cov ntawv sib txawv (cov kab zoo, cov kab ntxhib, cov kab tawv, thiab lwm yam), xim sib txawv, thiab qib gloss sib txawv (matte, tiaj tus, siab-gloss).

Sandblasting

Sandblasting yog ib qho ntawm cov kev kho mob feem ntau siv rau cov khoom kho vajtse.Nws tuaj yeem txhim kho qhov huv thiab roughness, thiab ua kom cov adhesion thiab durability ntawm cov khoom thiab txheej.Yog li ntawd, ntau qhov chaw kho mob xaiv sandblasting raws li lawv txoj kev kho ua ntej.Xws li: sandblasting + oxidation, sandblasting + electroplating, sandblasting + electrophoresis, sandblasting + dusting, sandblasting + xim, sandblasting + passivation, thiab lwm yam.

Teflon txau

Kuj hu ua Teflon txau, nws yog ib qho kev kho mob tshwj xeeb heev.Nws muaj cov yam ntxwv zoo ntawm kev tiv thaiv viscosity, tsis muaj viscosity, kub tsis kam, tsis tshua muaj kev sib txhuam, siab hardness, tsis ntub dej, thiab tshuaj lom neeg ua haujlwm siab.Yog li ntawd, nws yog dav siv hauv kev lag luam khoom noj khoom haus, tableware, kitchenware, ntawv kev lag luam, khoom siv kho mob, khoom siv hluav taws xob thiab tsheb, cov khoom siv tshuaj, thiab lwm yam, thiab tuaj yeem tiv thaiv cov ntaub ntawv los ntawm cov tshuaj tiv thaiv corrosion kom ntev kev pab cuam lub neej ntawm cov khoom.

Etching

Etching yog cov txheej txheem ntawm kev tshem tawm cov khoom siv tshuaj lom neeg los yog kev cuam tshuam lub cev.Feem ntau yog hais txog etching, tseem hu ua photochemical etching, uas yog hais txog kev tshem tawm cov yeeb yaj kiab tiv thaiv ntawm thaj chaw yuav tsum tau etched tom qab raug phaj ua thiab kev loj hlob, thiab tiv tauj cov tshuaj tov thaum lub sij hawm etching kom tiav cov nyhuv ntawm dissolution thiab corrosion, tsim cov nyhuv. concave-convex los yog hollow molding.

IMD

Hauv Pwm Kho Kom Zoo Nkauj (IMD) yog tus nqi zoo ntawm kev kho kom zoo nkauj ntawm cov khoom yas.Nws muaj plaub theem: Printing, Forming, Trimming thiab Txhaj Molding.Thiab Nws yog thoob ntiaj teb nrov nto kho kom zoo nkauj tshuab.Qhov saum npoo yog tawv thiab pob tshab zaj duab xis, nruab nrab txheej txheej txheej txheej, rov qab txhaj tshuaj molding txheej, thiab nruab nrab ntawm tus number case tuaj yeem ua rau cov khoom tiv thaiv kev sib txhuam., tiv thaiv qhov chaw los ntawm khawb, thiab tuaj yeem ua kom cov xim ci thiab tsis yooj yim kom ploj mus ntev.

Pad Printing

Pad luam ntawv, tseem hu ua tampography lossis tampo luam ntawv, yog qhov tsis ncaj qha offset (gravure) luam ntawv txheej txheem uas silicon ncoo siv 2-D duab los ntawm laser engraved (etched) luam ntawv phaj (tseem hu ua cliché) thiab hloov mus rau 3- D yam.Ua tsaug rau cov ntawv luam tawm, tam sim no muaj peev xwm luam tawm txhua yam ntawm cov khoom nyuaj xws li nkhaus (convex), hollow (concave), cylindrical, kheej kheej, cov ces kaum sib txuas, textures, thiab lwm yam uas tsis muaj nrog cov txheej txheem luam ntawv.

Dej hloov luam ntawv

Dej hloov luam ntawv yog ib hom luam ntawv uas siv dej siab los hydrolyze cov ntawv hloov pauv / yas zaj duab xis nrog cov qauv xim.Cov txheej txheem thev naus laus zis suav nrog kev tsim cov ntawv hloov pauv dej, ntim cov ntawv paj, hloov cov qauv, ziab, thiab cov khoom tiav.

Cov txheej txheem conductive

Conductive txheej yog ib hom xim uas siv tau rau kev txau.Nws tuaj yeem ua hluav taws xob tom qab ziab kom tsim cov xim pleev xim, kom tiv thaiv electromagnetic cuam tshuam.Tam sim no, nws yog siv nyob rau hauv ntau yam tub rog thiab pej xeem kev lag luam teb xws li electronics, khoom siv hluav taws xob, aviation, tshuaj lom neeg kev lag luam, luam ntawv, thiab lwm yam.

Lub sij hawm xa tuaj: Plaub Hlis-11-2023