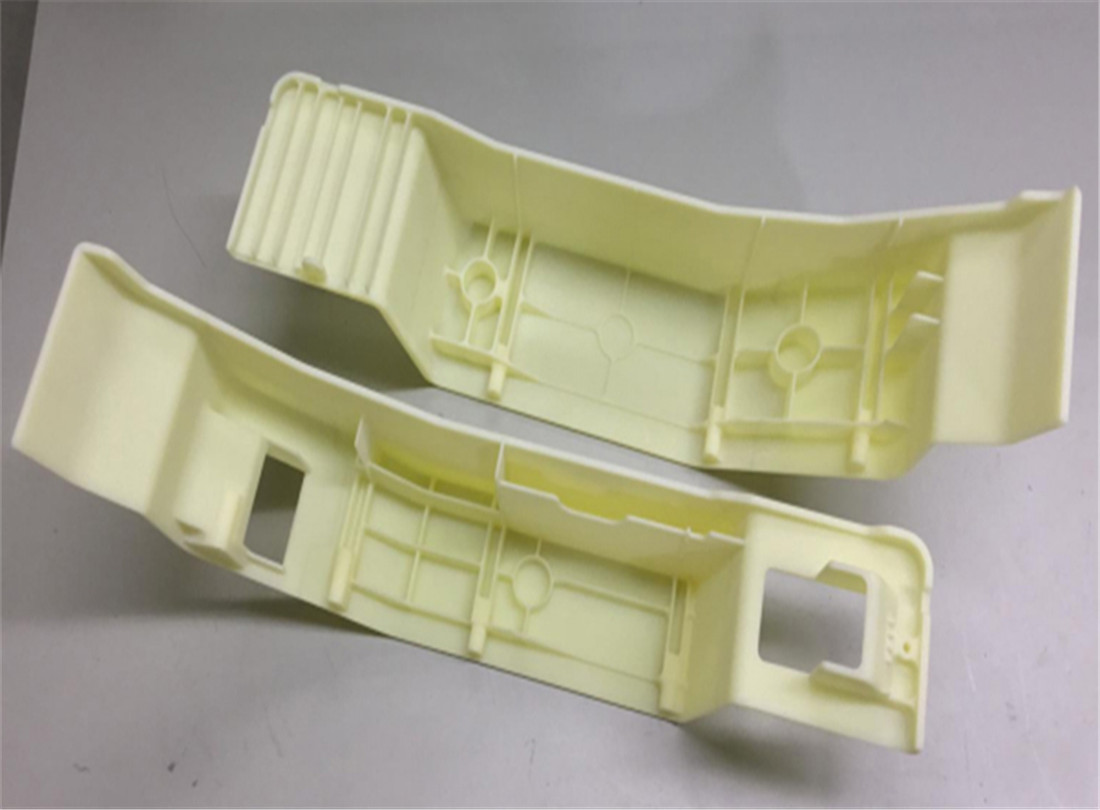

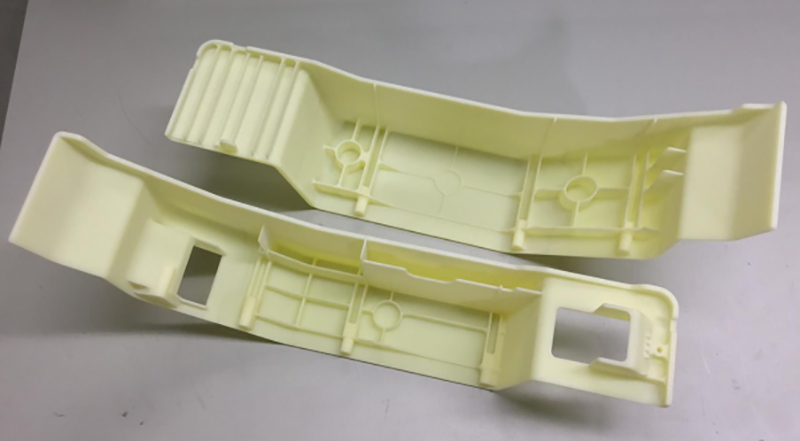

Tshiab RCT CNC Machining ABS yas qhov qauv qauv rau kev tsim khoom

Peb muab cov kev daws teeb meem ua tiav rau kev tsim qauv rau kev tsim khoom loj kawg raws li koj cov qauv CAD.Peb tsis tsuas yog ua cov khoom siv CNC zoo nkaus xwb tab sis peb kuj muaj cov kab tag nrho ntawm cov kev pabcuam tiav nrog rau kev pleev xim, xuab zeb, ntawv luam ntawv thiab lwm yam.Peb yuav pab koj tsim qhov chaw rau cov chav ua yeeb yam zoo tshaj plaws, cov qauv kuaj engineering, kev sib tw pab pawg neeg coob coob thiab ntau dua.

Nyob rau hauv cov khoom tshiab tsim thiab kev loj hlob txheej txheem, CNC machining ABS qauv yog ib qho ntawm feem ntau prototypes, accounting rau txog 75% ntawm tag nrho cov nyiaj ntawm yas qauv.Qhov no yog vim CNC machining ABS yog ib qho zoo engineering yas, lub zog yuav ua tau zoo heev kom tau raws li qhov xav tau ntawm txhua yam kev tsim qauv.Xws li kev sim ua haujlwm, sib tsoo, pleev xim, plating thiab lwm yam.Polished ABS cov ntaub ntawv, ces nws yog yooj yim dua, thiab qhov saum npoo kuj tau lees tias yuav du.Thiab qhov tseeb kuj zoo heev, feem ntau yog cov qauv yuav tsum tau pleev xim rau, chrome plated, thiab silk screen, ces cov nplaum nplaum yog zoo dua, polish heev.

CNC Machining ABS yas qhov qauv qauv kuj zoo tagnrho rau ntau yam kev siv, suav nrog:

●Suab paj nruag

●Lub log npog

●Auto lub cev qhov chaw

●Cov ntaub thaiv npog

●Pwm nrog floating core

●Cov khoom ua si

●Kev tiv thaiv headgear

Khoom Parameter rau CNC Machining ABS yas qhov qauv qauv

| Avaliable Production process | CNC machining, milling, drilling, sawing, tig, shearing, threading, |

| Cov khoom siv tau | Ntuj ABS, Dub ABS, Dawb ABS |

| Txheem raug | ± 0.1mm, tshwj xeeb yuav tsum tau ua ± 0.05mm |

| Qhov siab tshaj qhov seem | 1900 x 900 x 750 mm |

| Kev kho saum npoo | du, pleev xim rau, chrome plated, thiab silk screen .. thiab lwm yam |

| MOQ | 1 Pcs |

| Ua ntej lub sijhawm | Lub sijhawm luv tshaj plaws yog 3 hnub los ntawm kev txiav txim kom xa |

| Kev soj ntsuam System | Cov kws kho mob kuaj tus kheej & Tus kws kho mob kuaj xyuas thaum lub sijhawm tsim khoom |

| Kev cob qhia QA yuav ua qhov kev tshuaj xyuas zaum kawg rau txhua qhov ntawm txhua tus nqi txhawm rau txheeb xyuas qhov kam rau ua, kev ua haujlwm, kev sib dhos, qhov pom ntawm qhov chaw tiav los ntawm kev pabcuam ntawm CMM, Projector, pin gauges, qhov siab ntsuas, ntsuas lub vojvoog..etc. |

RCT MFG-Koj Lub Tuam Txhab Txhim Kho Kev Ua Haujlwm Zoo Tshaj Plaws

Yog tias koj tab tom nrhiav tus xa khoom sai sai hauv Suav teb, RCT MFG tuaj yeem yog koj tus khub zoo tshaj plaws.

Feem ntau, nws yog ib qho nyuaj heev los xaiv tus neeg muag khoom tshiab los muab kev pabcuam prototyping sai, tuaj yeem ua tus qauv pub dawb sai sai rau koj pom zoo.

Tom qab tau txais kev pom zoo ntawm thawj tus qauv prototyping sai, peb yuav npaj lwm yam kev hloov pauv sai sai.Yog tias koj xav tau cov kev pabcuam prototyping sai, cia li xa peb email.

Thaum lub sij hawm sai prototyping manufacturing, Peb pab neeg technical thiab muag khoom yuav muab kev hloov tshiab thiab tawm tswv yim ntawm cov prototyping sai sai nyob rau hauv lub sij hawm.Koj yuav paub ntau ntxiv txog koj sai prototyping txheej txheem.

Peb nyob ntawm kab ib txwm rau koj, tsuas yog xa cov ntsiab lus info txog koj qhov project prototyping sai.

Pwm machining tshuab